7

March

Assistant Professor Jason Peters receives grant to re-engineer bacteria for biofuel

By Katie Gerhards

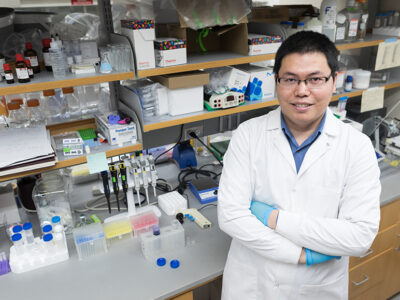

Jason Peters is one of thousands of scientists worldwide aiming to curb the impact of antimicrobial resistance, which is one of the World Health Organization’s (WHO) 10 threats to global health in 2019. Peters is taking a unique approach to that problem, using CRISPR-based techniques to identify genetic functions necessary for pathogenic bacteria to live, which can then be targeted with new antibiotics.

In a new project, Peters, an assistant professor in the University of Wisconsin–Madison School of Pharmacy’s Pharmaceutical Sciences Division, will be using that same gene-modifying technology in an attempt to curb the top threat on WHO’s list: climate change.

Through an Emerging Opportunity grant from the Great Lakes Bioenergy Research Center (GLBRC), a U.S. Department of Energy (DOE) Bioenergy Research Center led by UW–Madison, Peters will be helping to engineer bacteria to produce promising biofuels.

“A lot of what I’ve been doing is developing new tools to study bacteria, look at how antibiotics work, and find new potential targets in the cell for antibiotics,” says Peters. “But those tools don’t necessarily need to be applied to a very specific question — they can be applied to many questions.”

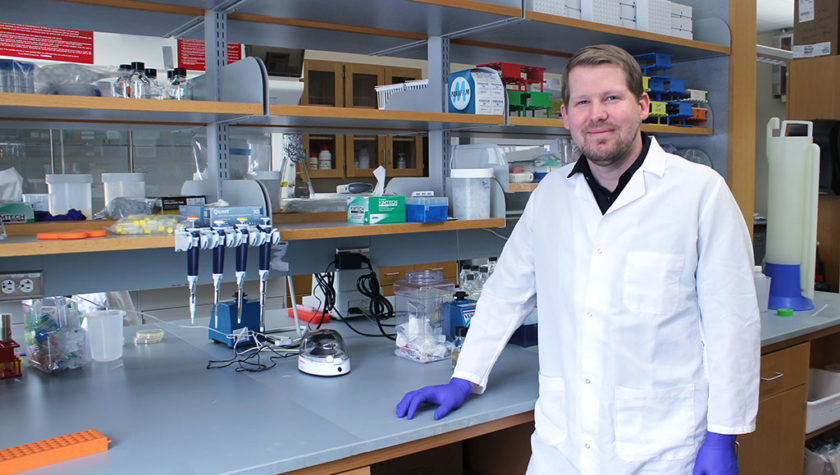

DOE has recognized bioenergy as one of multiple strategies that are necessary to stave off the worst impacts of climate change, says Robert Landick, GLBRC science director and professor of biochemistry at UW–Madison. He is hoping Peters’ tools and expertise can provide answers to some of the questions surrounding biofuels.

CRISPR technology allows more rapid, accurate, and informed ways of engineering of genomes, says Landick, which can help researchers conquer current hurdles in biofuel production.

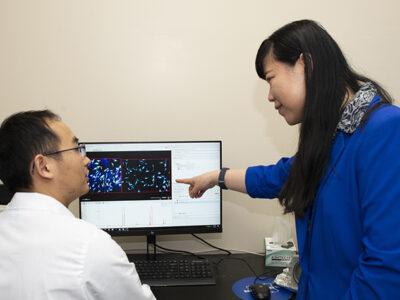

“This is an area of expertise Dr. Peters was integral in helping develop, and he wrote one of the landmark papers about CRISPR as a technology for probing gene expression in a high-throughput way, called CRISPR interference, or CRISPRi,” says Landick. “So when he came to the UW–Madison School of Pharmacy as a new faculty member, GLBRC viewed his expertise as something that would be highly valuable to add to our research capabilities.”

Through the grant, Peters will be working with collaborators within GLBRC to engineer bacteria, such as Zymomonas mobilis, to produce isobutanol, a less volatile and higher-energy alternative to ethanol as a replacement for gasoline.

Overcoming biofuel barriers

Corn on the cob makes a regular appearance on the plates and grills of people around the world — but you won’t find people snacking on the stalks and leaves. That’s because the nutrients in those parts of the plant are more difficult to access, even for bacteria.

“It’s very difficult to have an organism that will consume those nutrients and then convert them into something valuable like a biofuel,” says Peters.

Before plant biomass can be converted into biofuels, it goes through a pretreatment step to break down the plant cell walls and make the sugars inside more accessible. The result is hydrolysate, a sludgy mixture of partially digested plant material that is more manageable for bacteria to consume. Hydrolysate, however, is full of toxic compounds that are used to break the material down, and it’s difficult for bacteria to stay alive in that environment.

“It’s incredibly stressful for the bacteria, so they eventually die in the process and shut down their metabolism, ending the production of isobutanol,” says Landick. “So to really make that work well, we need to figure out how to overcome that stress response.”

There are two ways to overcome this problem: one is to allow bacteria to grow in that condition and hope they’ll adapt, or you take a more proactive approach and individually perturb genes to see which are important in growing in that condition. That’s where Peters’ role comes into play.

“Using my CRISPR technique, I can see how the toxic compounds in hydrolysate affect the growth of the bacterium, and then I can identify which genes to change to make the bacteria more resistant to those toxins,” explains Peters.

As Peters finds genetic leads, collaborators within GLBRC will use them to reengineer bacteria to better survive while producing isobutanol.

“There’s an entire chain of research set up in the Center that generates the sugar material that the bacteria are converting to isobutanol, so the modified organisms need to be tested in the context of this entire chain,” says Landick.

Making biofuels commercially viable

GLBRC, which is led by UW–Madison with Michigan State University as a major partner, has conducted foundational research on biofuels since being funded by DOE in 2007.

“One of the key parts of making biofuels a net positive for climate change and sustainability is to make sure you’re not doing it in a way that’s competing with production of food,” says Landick. “Using the food supply is a zero-sum game, and if you’re relying on the same sources, anything you do to make biofuels will be interfering with agricultural production.”

Ethanol, for example, is a commonly used biofuel that, in the U.S., is often made from corn starch, which means it competes directly with the food supply. Ethanol is also somewhat volatile and has a lower energy content than gasoline, making a less-than-ideal alternative fuel. The isobutanol that Peters will help to produce will be made from inedible plant material, will be less volatile, and will be a more direct replacement for gasoline.

“This goal of creating a commercially viable biofuel requires a lot of biological knowledge, engineering knowledge, chemistry knowledge,” says Peters. “It’s not a goal that one person can achieve; it takes a group effort.”

Learn more about the research in Assistant Professor Jason Peters’ lab and his CRISPRi technique.

!["When [Peters] came to the UW–Madison School of Pharmacy as a new faculty member, GLBRC viewed his expertise as something that would be highly valuable to add to our research capabilities."](/wp-content/uploads/Pull-Quote_Landick-Peters-300x125.png)